Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Loading

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

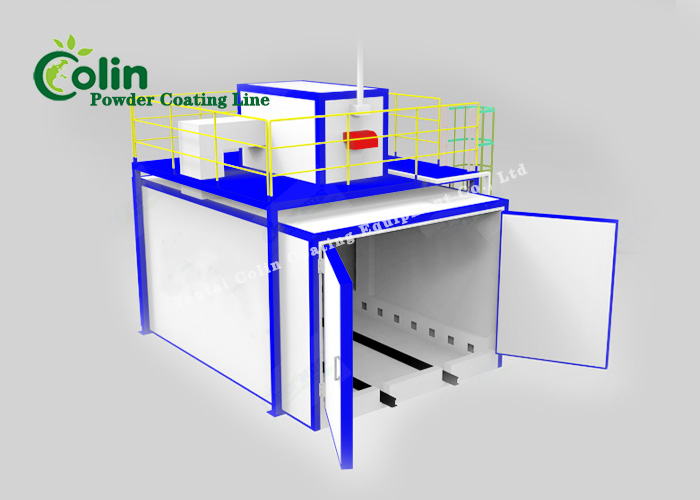

Powder Coating oven is one of the key equipment in the spraying system, ensuring the final spraying effect.

Powder curing oven can be divided into batch curing oven ,bridge type powder coating oven, tunnel type powder coating oven according to demand

Batch Type curing oven

1. Easy to operate and maintain

2. Affordable price and stable performance

3. This type of curing oven is usually used for manual powder spraying lines.

4. Configurable top track and ground track carts can be used in conjunction with other conveying methods

5. The ovens are made of galvanized sheet and rock wool board

Tunnel Type curing oven

Tunnel type curing furnaces are usually long and residential, suitable for slender or small products such as pipelines and aluminum profiles.

1. Heat source: natural gas/electricity/diesel, etc.

2. Fast heating speed and high thermal efficiency.

3. Equipped with Colin patented technology, it has low heat loss and energy consumption, and even heat distribution.

Bridge Type Curing Oven

This type of curing oven is suitable for large spraying lines and can reduce the use of space.

The special design of the box provides better temperature control.

Specially designed to share the functions of moisture drying and powder solidification in one box, significantly reducing energy consumption.